Overhead Conveyor type machines are suitable for

very high volume production or for fully automated plants with

conveyors for part handling.

Overhead Conveyor type machines are suitable for very high volume production or for fully automated plants with conveyors for part handling. The overhead conveyors are custom designed to suit individual plant requirements. The conveyors can be easily integrated with the existing processes or existing conveyors.

The parts to be blast cleaned are mounted on hooks and are carried to the blast chamber. The loading and unloading points can be same or at different locations depending on individual requirement.

The components rotate inside the blast chamber for thorough cleaning. For high speed machines the wheels are so arranged that the components get cleaned from all sides in a single pass without any rotation. This arrangement is suitable for components like silencers, chassis, various structures, etc.

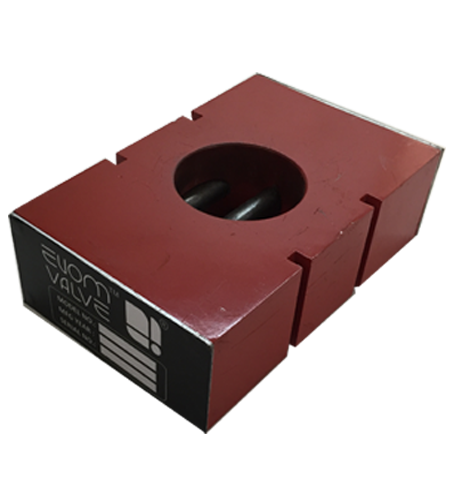

Euom Valve® is a cost effective and ultra modern shot flow control valve that uses an ingenious approach to achieve shot flow control. The valve operates on the theory of electro-magnetism

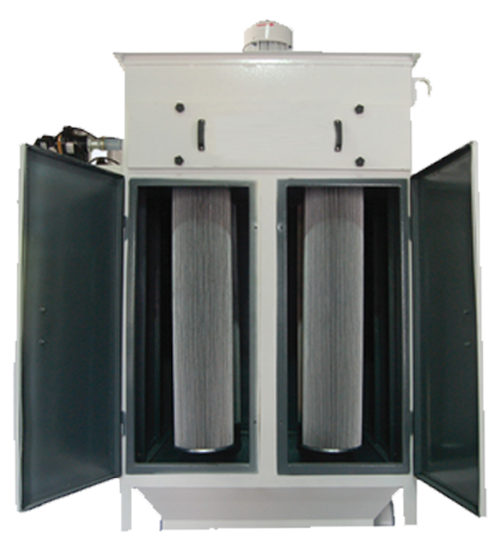

High Efficiency Reverse Pulse Jet Type Dust Collector

| MODEL | PE. OHC - 1 | PE. OHC - 2 | |||

| Load Capacity [kgs] | Up to 450 | Up to 1500 | |||

| Hanger Dimensions [mm] | 1000 X 1200 | Customized | |||

| No of Blast Wheels | 2 | 3 up to 8 | |||

| Blast Wheel Size [inches] | 15 or 19.5 | 15 or 19.5 | |||

| Blast Wheel Drive | Direct motor mounted or Indirect drive | ||||

| Blast Wheel Design | Single plate or Double plate design | ||||

| Shot Flow Control Valve | Electro-magnetic/Pneumatically operated | ||||

| Turbine Motor [Hp] | 5 / 7.5 | 7.5/10 | 10/15 | 10 and above | |

| Electricals | • Main Supply: 440V, 50 Hz, 3 phase • Control Circuit and Instrumentation - 24Vdc. |

||||

| Sound Level | <80 dB at a distance of 1 meter from the machine | ||||

| Dust Collector | High Efficiency Reverse Pulse Jet Type Dust Collector | ||||