Online Wire Rod Shot Blasting Machines

We are Manufacturer, Supplier, Exporter, Services Provider of Online Wire Rod Shot Blasting Machines, and our setup is situated at Aurangabad, Maharashtra, India.

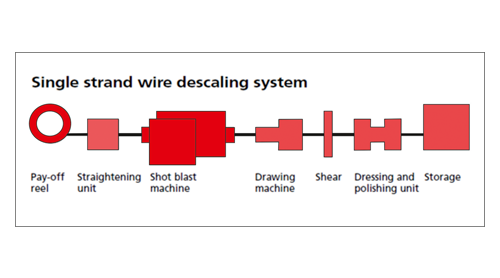

Single Stand Wire Descaling System

The ideal production line with the shot blasting machine integrated is shown in the figure. The machine works in-tandem with the complete line. The wire strand is pulled from the reel by the drawing/straightening unit. After the wire is straightened it is fed into the shot blasting machine. The cleaning speed of the machine is matched with the drawing line speed. The descaling speed is generally set to suit the type of scale, the material being processed and the degree of surface cleanliness desired. The thoroughly cleaned wire then enters the drawing machine. The full-proof operation ensures that the machine stops if the production line is interrupted anywhere during production.

The shot blast equipment consists of the following:

- System for handling wire and bar

- Shot blast machine

- Dust collector

Features

- Pit less and low height machine design

- MARSH - High Life Carbide Alloy Wear Parts.

- MARSH - High Performance Blast Wheels

- Three stage seals to ensure zero shot and dust leakages from the blast chamber.

- 1/2" thk Mn. Steel blast wheels housings with machined alloy steel liners

- Easy accessibility to all maintenance areas and easy replacement of wear parts.

- High Efficiency Dust Collector.

- Fool-proof and intelligent machine control system.

- Euom Valve for precise shot flow control.

Optional Features

- Complete Mn. Steel construction

- Sound insulation enclosures.

- Automated fire fighting systems for dust collector

- Range of performance, maintenance, safety and data acquisitions systems

- Vibro-sieves for shot size filtration.

MARSH - High Performance Blast Wheels

- Blasting can be done at high speeds, up to 3,600RPM. This increases the productivity for the same blast wheel motor Hp and also allows for higher compressive stress generation

- Approx 40% less current consumption compared to conventional designs.

- 1/2"thk Mn. Steel Housing is for life.

- Only 03 nos of blast wheel housing liners are required.

- The blast wheel is easily accessible by removing the front circular liner.

- The complete assembly / dismantling can be done by single person in fewer than 15 mins.

- Can be used for any magnetic abrasive media.

- Cast parts are completely eliminated. Blades, control cage and impeller cage are manufactured from special carbide alloy. Blast wheel and housing liners are manufactured from forged tool steel blocks.

- Extremely silent operation due to precision manufacturing and design innovation.

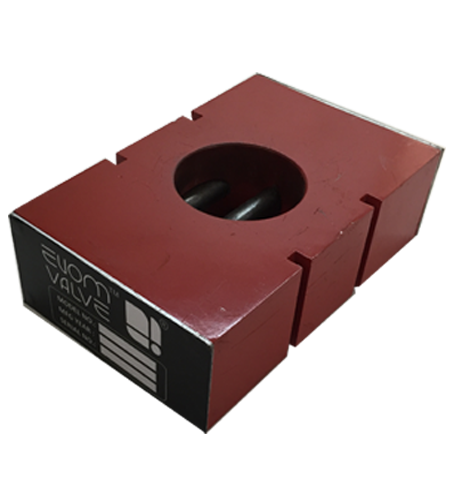

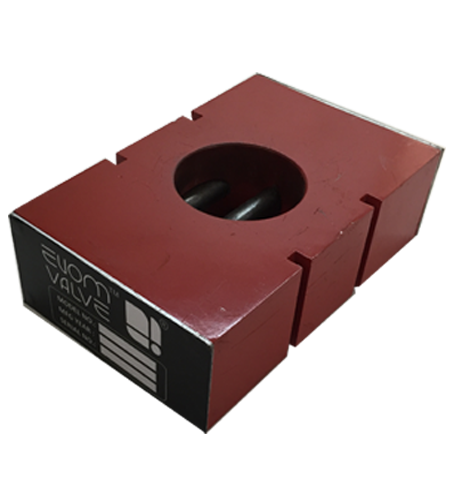

EUOM Valve

Euom Valve® is a cost effective and ultra modern shot flow control valve that uses an ingenious approach to achieve shot flow control. The valve operates on the theory of electro-magnetism

- No moving parts and no maintenance required.

- The shot flow can be precisely set from the control unit.

- The actual flow is displayed on the control unit screen.

- No additional source like compressed air, etc required for its operation.

- 24Vdc operated.

- Shot Flow Sensor ensures that the set shot flow rate is actually achieved.

- Can be used for any magnetic abrasive media.

- The valve will give an error alarm and can trip the machine if the flow rate varies beyond the user specified limit.

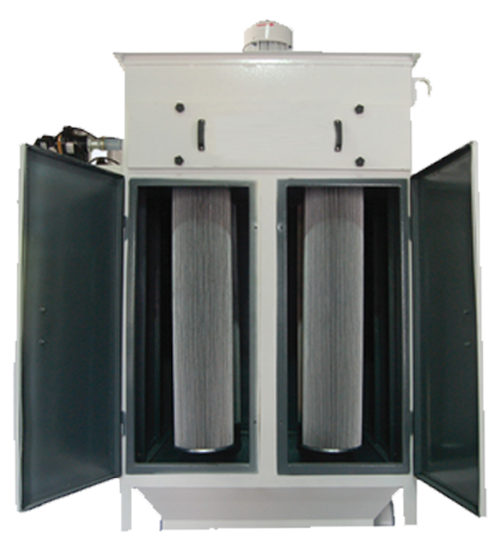

Dust Collectors

High Efficiency Reverse Pulse Jet Type Dust Collector

| Line Speed |

Up to 180 mtrs/min |

| Cross Section |

|

| Wire Diameter |

3mm and above |

| No of Blast Wheels |

2, 3, 4, 6,8 |

| Blast Wheel Size[inches] |

12 / 15 |

| Blast Wheel Drive |

Direct Drive or Indirect drive |

| Blast Wheel Design |

Single plate or Double plate design |

| Shot Flow Control Valve |

Euom Valve |

| Shot re-circulation System |

Motorized screw conveyor with hard faced flights |

| Bucket Elevator |

Multi-ply rubber belt with alloy steel buckets |

| Shot Separator |

Counter flow air wash system with multiple baffles |

| Dust Collector |

Mechanical Shaker or Reverse Pulse Jet type |

| Power Requirement [Hp] |

Variable, Depending on machine configuration |

| Electricals |

• Main Supply: 440V, 50 Hz, 3 p

• Hase

• Control Circuit and Instrumentation - 24Vdc.

|